Home > News and Media > News and Events > Angular Contact Ball Bearings: Single or Paired Use?

Abstract:

Angular contact ball bearings can be used individually or in pairs, depending on the specific application requirements. Single use is suitable for space-constrained applications with minimal axial load, whereas paired use is ideal for applications requiring high precision, high rigidity, and the ability to handle complex loads.

Key words: Angular contact ball bearing, single use, paired use, DB, DF, DT

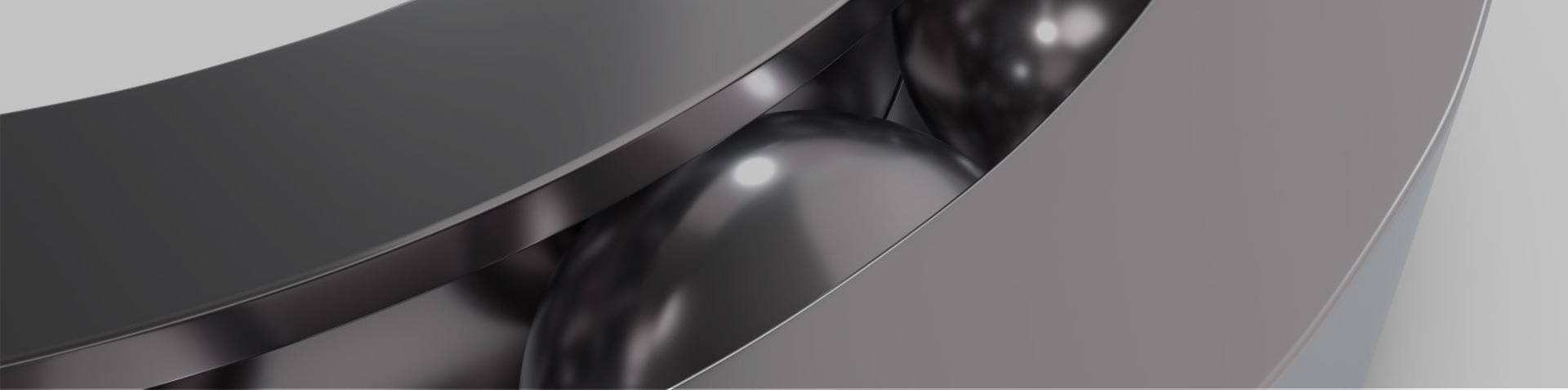

Angular contact ball bearings are a type of high-precision bearing commonly used in various mechanical systems. Their unique design allows them to accommodate both radial and axial loads, making them an essential component in applications requiring high-speed and high-precision performance. However, one frequently asked question is: should angular contact ball bearings be used individually or in pairs? This article explores their structural characteristics, application scenarios, and installation methods to help users make informed decisions.

Structural Characteristics of Angular Contact Ball Bearings

Angular contact ball bearings are designed with raceways in the inner and outer rings that are positioned relative to each other at a specific contact angle (typically 15°, 25°, or 40°). This feature enables them to handle both radial loads and unidirectional axial loads. The ability to handle axial loads improves as the contact angle increases, making these bearings suitable for applications with significant axial forces.

However, due to their unidirectional axial load capacity, angular contact ball bearings may face limitations when used individually in applications requiring bidirectional axial load handling or combined loading. This limitation is one of the main reasons why angular contact ball bearings are often used in pairs.

Applications for Single Use

When used individually, angular contact ball bearings are suitable for the following scenarios:

Unidirectional Axial Load Applications: For example, machinery that experiences axial force in only one direction.

Primarily Radial Load Applications: In some cases, the axial load is minimal, and the primary load is radial, making single use sufficient.

Space-Constrained Applications: Single bearings are often preferred in compact designs where space is limited.

Applications for Paired Use

When angular contact ball bearings are used in pairs, the installation configuration can vary based on the application requirements. The three common pairing methods are:

Back-to-Back Configuration (DB): The large ends of the bearings face away from each other, forming a “V” shape with the contact angles. This setup provides excellent rigidity, can handle high radial loads and bidirectional axial loads, and is ideal for resisting overturning moments.

Face-to-Face Configuration (DF): The small ends of the bearings face each other, with the contact angles converging inward. This arrangement offers lower rigidity compared to back-to-back configurations but accommodates slight misalignment and axial displacement.

Tandem Configuration (DT): The contact angles of both bearings point in the same direction, allowing them to share the load in a single axial direction. This setup is often used in applications requiring high axial load capacity.

Bidirectional Axial Load Applications: For example, CNC machine spindles, precision instruments, and industrial robots often require bearings to handle axial forces in both directions.

High-Rigidity Applications: Equipment such as aerospace machinery and high-precision machine tools require high stiffness and rigidity to ensure performance under heavy loads.

Overturning Moment Resistance: Applications like turntables and rotary tables benefit from paired bearings that can withstand large moment loads.

Conclusion

Angular contact ball bearings can be used individually or in pairs, depending on the specific application requirements. Single use is suitable for space-constrained applications with minimal axial load, whereas paired use is ideal for applications requiring high precision, high rigidity, and the ability to handle complex loads.

When deciding between single or paired use, it is essential to consider the operating conditions, load characteristics, and system design requirements. Regardless of the configuration, proper installation and maintenance are critical to ensuring optimal bearing performance and longevity.

By understanding the differences between single and paired use, users can make informed decisions that maximize the efficiency and reliability of their machinery.

Send a message directly to us. We will contact you at once.