Home > News and Media > News and Events > Grease lubrication and oil lubrication of bearings

Abstract:

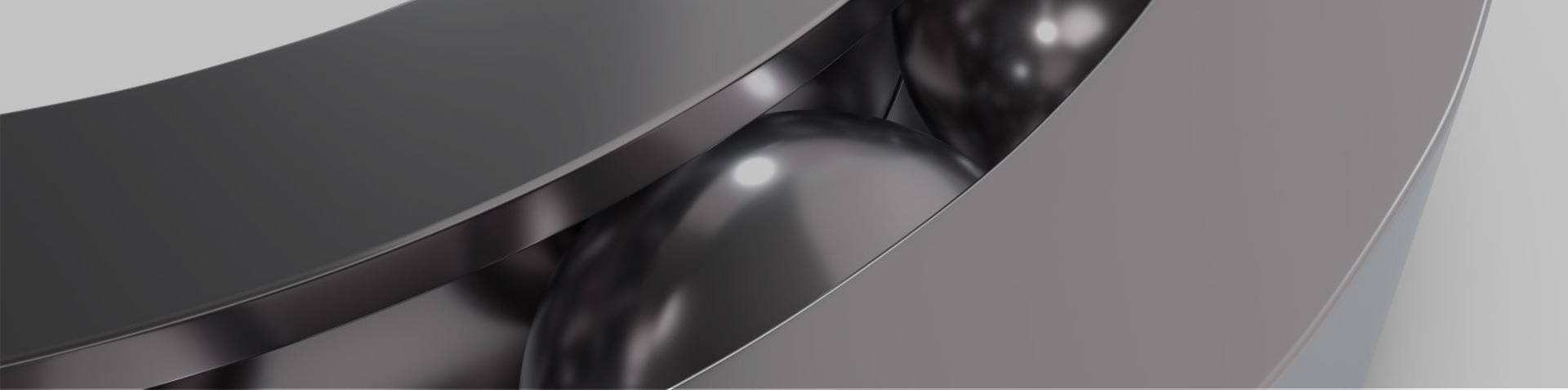

The main purpose of bearing lubrication is to use lubricant to form an isolating lubricating oil film on the friction surfaces between the rings, rolling elements and cages to reduce bearing friction and wear, prevent sintering, and extend the service life of the bearing. In addition, lubricants can also prevent bearing corrosion, reduce vibration and noise, provide cooling, and prevent the intrusion of external foreign matter.

Key words: Grease lubrication, oil lubrication, bearing lubrication, high-speed precision bearings, oil mist lubrication, oil-gas lubrication, oil injection lubrication.

The main purpose of bearing lubrication is to use lubricant to form an isolating lubricating oil film on the friction surfaces between the rings, rolling elements and cages to reduce bearing friction and wear, prevent sintering, and extend the service life of the bearing. In addition, lubricants can also prevent bearing corrosion, reduce vibration and noise, provide cooling, and prevent the intrusion of external foreign matter.

Grease lubrication

The most commonly used grease for rolling bearings is bonded grease with mineral oil as the base oil. This grease has good adhesion and has good lubrication effect in a wide temperature range and speed range. The applicable temperature range is -30°C~+110°C.

Oil lubrication

When grease lubrication cannot meet the high performance requirements of the machine tool, oil lubrication can be used. The most commonly used oil lubrication methods for machine tool spindle bearings include oil mist lubrication, oil-gas lubrication, and oil injection lubrication.

|

Lubrication method |

Advantages |

|

Oil mist lubrication |

New lubricating oil is continuously injected, oil deterioration will not occur. Dust and cutting fluid are not easily infiltrated |

|

Oil-gas lubrication |

It can control the optimal amount of oil, with low bearing heating, good cooling effect and low temperature rise. Dust and cutting fluid are not easily immersed. No environmental pollution. |

|

Oil injection lubrication |

Due to the large flow rate, dust and cutting fluid will not enter the bearings and will not burn the bearings. The oil injection takes away the heat and the temperature rise of the bearing can be controlled. |

To learn more about BRZB bearings, please visit www.brzbearing.com or send email to sales@brzbearing.com.

Send a message directly to us. We will contact you at once.