Home > News and Media > News and Events > High Precision Bearings: The Backbone of Semiconductor Manufacturing

Abstract:

In the intricate world of semiconductor manufacturing, where precision is the key to success, high precision bearings play a critical role in ensuring the smooth and efficient operation of equipment. As the industry pushes the boundaries of technology further, the importance of these tiny yet indispensable components will only continue to rise, underpinning the very foundation of modern innovation.

Key words: High precision Bearings, Angular contact ball bearing, Bearing for Semiconductor Manufacturing

In the intricate world of semiconductor manufacturing, where precision is paramount and margins for error are virtually nonexistent, the role of high precision bearings cannot be overstated. These tiny yet crucial components form the very backbone of the machinery that drives the production of semiconductors, the building blocks of modern technology.

At the heart of semiconductor manufacturing processes lie a myriad of equipment such as wafer handling robots, lithography machines, and etching tools, all of which rely on high precision bearings to ensure smooth, accurate, and reliable operation. These bearings are designed to withstand the rigorous demands of the semiconductor industry, where nanometer-level accuracy is the norm.

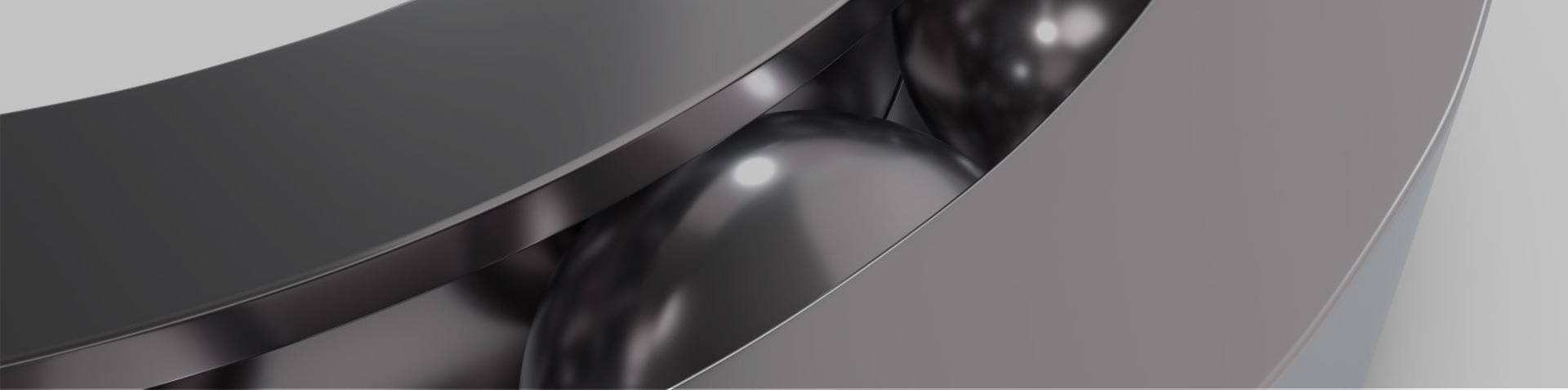

What sets high precision bearings apart is their exceptional engineering and manufacturing standards. These bearings are crafted with meticulous attention to detail, using advanced materials and cutting-edge technologies to achieve unparalleled levels of precision and reliability. From angular contact bearings to ceramic hybrid bearings, each type serves a specific purpose, catering to the diverse needs of semiconductor manufacturing processes.

The use of high precision bearings in semiconductor manufacturing offers a host of benefits, including:

Precision and Accuracy: High precision bearings ensure precise movement and positioning of components, critical for the intricate processes involved in semiconductor production.

Durability and Reliability: Designed to operate in demanding environments, these bearings offer exceptional durability and reliability, minimizing downtime and enhancing productivity.

Enhanced Performance: By reducing friction and wear, high precision bearings help optimize the performance of semiconductor manufacturing equipment, leading to improved efficiency and quality.

Cleanroom Compatibility: Many high precision bearings are specially designed to meet the stringent cleanliness requirements of semiconductor cleanrooms, ensuring contamination-free operation.

As the semiconductor industry continues to evolve and innovate at a rapid pace, the demand for high precision bearings will only grow. With the advent of technologies such as AI, IoT, and 5G driving the next wave of semiconductor advancements, the need for bearings that can meet the increasingly stringent requirements of these applications will be paramount.

In the intricate world of semiconductor manufacturing, where precision is the key to success, high precision bearings play a critical role in ensuring the smooth and efficient operation of equipment. As the industry pushes the boundaries of technology further, the importance of these tiny yet indispensable components will only continue to rise, underpinning the very foundation of modern innovation.

Send a message directly to us. We will contact you at once.