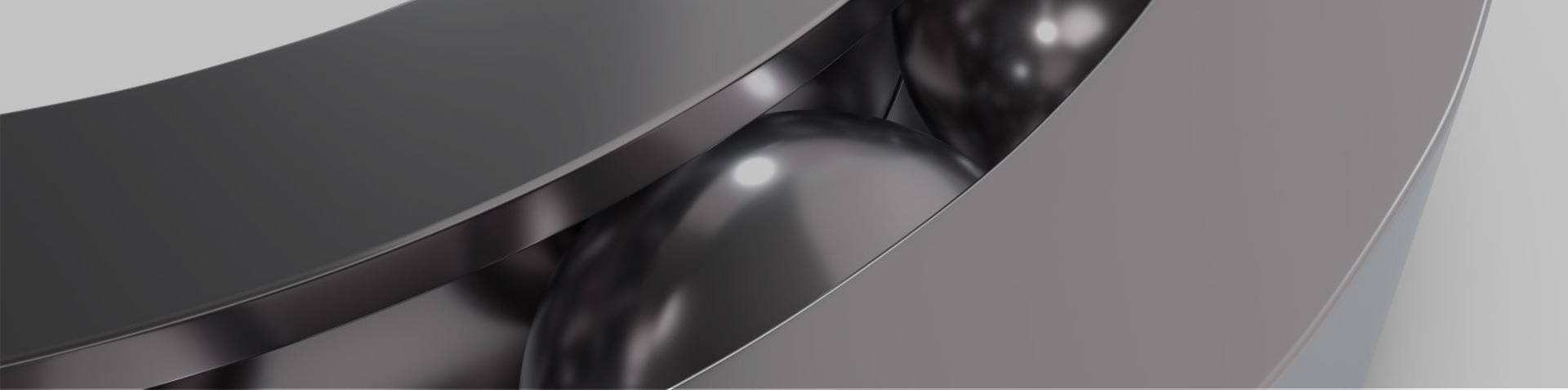

Home > News and Media > News and Events > How do environmental conditions affect the performance and service life of angular contact ball bearings?

Abstract:

It is crucial to consider the anticipated temperature and humidity conditions during the selection and application of angular contact ball bearings. Manufacturers provide guidelines and recommendations regarding the temperature and humidity limits within which the bearings can operate effectively. Adhering to these guidelines, implementing proper lubrication practices, maintaining suitable environmental conditions, and promptly addressing any moisture-related issues can help optimize the performance and extend the service life of angular contact ball bearings in various operating environments.

Key words: Angular contact ball bearings, bearing service life, bearing manufacturers

Environmental conditions, such as temperature and humidity, can significantly impact the performance and service life of angular contact ball bearings. Here’s how these factors can affect the bearings:

Temperature:

Extreme temperature conditions, whether excessively high or low, can have adverse effects on angular contact ball bearings:

a. High Temperatures: Operating at high temperatures can cause the lubricant to degrade more rapidly, leading to reduced lubrication effectiveness and increased friction. This can accelerate wear and potentially cause lubricant failure. Additionally, high temperatures can cause thermal expansion, leading to increased internal clearances and potential misalignment issues.

b. Low Temperatures: Cold temperatures can cause the lubricant to thicken, resulting in reduced lubrication effectiveness and increased resistance to rotation. Insufficient lubrication can lead to increased friction, wear, and potential damage to the bearing surfaces.

To mitigate the effects of temperature extremes, it is important to select angular contact ball bearings that are specifically designed for the anticipated temperature range. Additionally, implementing appropriate lubrication practices, such as using lubricants with suitable viscosity at the operating temperature, can help maintain optimal performance and extend the service life of the bearings.

Humidity:

Humidity, particularly high levels of moisture in the operating environment, can impact the performance and service life of angular contact ball bearings:

a. Corrosion: Moisture in the form of condensation or exposure to humidity can lead to corrosion of bearing components, including the rolling elements, raceways, and cages. Corrosion compromises the integrity of the bearing surfaces, resulting in increased friction, wear, and potential premature failure.

b. Lubricant Contamination: Moisture can also contaminate the lubricant, leading to lubricant degradation and reduced lubrication effectiveness. Contaminated lubricant can accelerate wear, increase friction, and contribute to bearing failure.

To mitigate the effects of humidity, it is important to implement appropriate sealing arrangements to protect the bearings from moisture ingress. Using corrosion-resistant coatings or materials for bearing components can also help combat the impact of humidity. Regular inspections and maintenance practices should be implemented to detect and address any signs of corrosion or moisture-related issues promptly.

It is crucial to consider the anticipated temperature and humidity conditions during the selection and application of angular contact ball bearings. Manufacturers provide guidelines and recommendations regarding the temperature and humidity limits within which the bearings can operate effectively. Adhering to these guidelines, implementing proper lubrication practices, maintaining suitable environmental conditions, and promptly addressing any moisture-related issues can help optimize the performance and extend the service life of angular contact ball bearings in various operating environments.

Send a message directly to us. We will contact you at once.