Home > News and Media > News and Events > The Advantages of Ceramic Balls for Angular Contact Ball Bearings

Abstract:

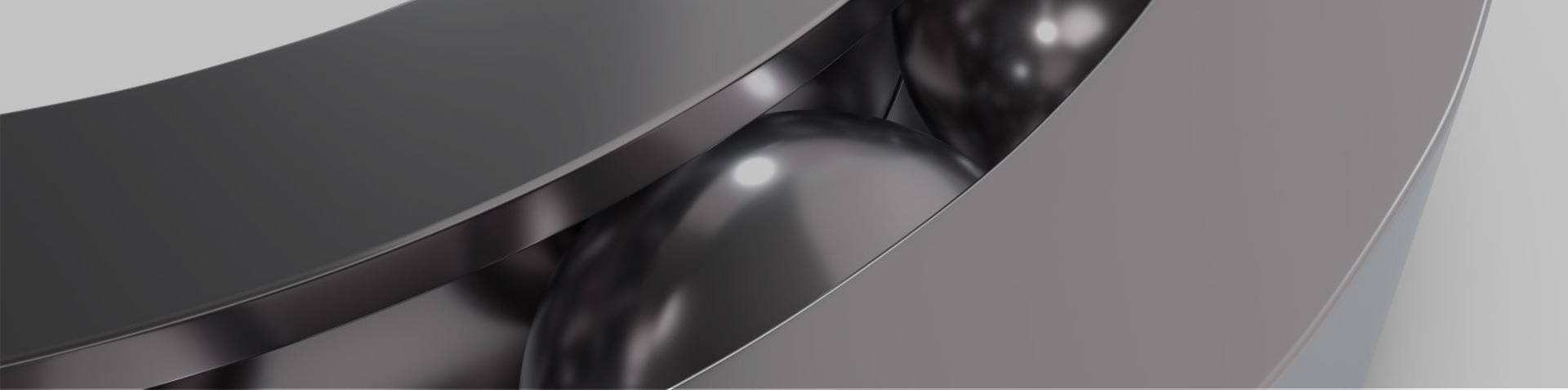

Angular contact ball bearings are critical components in high-speed and precision applications, offering excellent load-carrying capacity and rotational performance. One key factor that significantly influences the performance of these bearings is the choice of ball material. While steel balls have traditionally been used, ceramic balls are increasingly gaining recognition for their exceptional properties and numerous advantages. In this article, we explore why choosing ceramic balls for angular contact ball bearings can lead to improved performance, longevity, and overall operational efficiency.

Key words: Angular contact ball bearings, ceramic balls, Si3N4 balls, ball material, high-speed and precision applications

Angular contact ball bearings are critical components in high-speed and precision applications, offering excellent load-carrying capacity and rotational performance. One key factor that significantly influences the performance of these bearings is the choice of ball material. While steel balls have traditionally been used, ceramic balls are increasingly gaining recognition for their exceptional properties and numerous advantages. In this article, we explore why choosing ceramic balls for angular contact ball bearings can lead to improved performance, longevity, and overall operational efficiency.

Superior Hardness and Wear Resistance:

Ceramic balls, typically made from materials like silicon nitride (Si3N4) or zirconia (ZrO2), exhibit exceptional hardness and wear resistance compared to steel balls. Their hardness enables them to withstand high contact pressures without deformation or surface damage. This property significantly reduces the risk of pitting, spalling, and wear, resulting in extended bearing life and reduced maintenance requirements.

Reduced Friction and Heat Generation:

Ceramic balls have lower friction coefficients compared to steel balls, leading to reduced heat generation during operation. This characteristic is especially advantageous in high-speed applications, where excessive heat can cause lubricant degradation, premature wear, and bearing failure. By minimizing friction and heat, ceramic balls contribute to improved efficiency, lower operating temperatures, and enhanced overall performance of angular contact ball bearings.

High-Speed Capability:

One of the most notable advantages of ceramic balls is their ability to operate at significantly higher speeds compared to steel balls. Due to their lower density and excellent stiffness, ceramic balls exhibit lower centrifugal forces and reduced rolling resistance. These factors allow angular contact ball bearings with ceramic balls to achieve higher rotational speeds, making them ideal for applications that demand exceptional speed and precision, such as machine tools and spindle bearings.

Corrosion Resistance:

Ceramic balls possess excellent corrosion resistance, making them well-suited for operating environments with high humidity, moisture, or exposure to corrosive substances. Unlike steel balls, ceramic balls are not susceptible to rust or oxidation. This corrosion resistance ensures the integrity and longevity of the bearing even in challenging conditions, reducing the risk of premature failure and maintenance costs.

Electrical Insulation:

Another significant advantage of ceramic balls is their electrical insulation properties. This feature is particularly beneficial in applications where electrical currents or static electricity is present. Ceramic balls prevent the passage of electrical currents through the bearing, reducing the risk of electrical arcing, pitting, and damage. As a result, angular contact ball bearings with ceramic balls are commonly used in electric motors, generators, and other electrical equipment.

Lightweight Design:

Ceramic balls are significantly lighter than steel balls due to their lower density. This lightweight characteristic reduces the centrifugal forces acting on the bearings during high-speed rotation. The reduced forces contribute to lower bearing stress and improved fatigue life. Additionally, the reduced weight of ceramic balls allows for faster acceleration and deceleration, enhancing the dynamic response of the bearing system.

Conclusion:

Choosing ceramic balls for angular contact ball bearings can provide numerous advantages in terms of improved performance, extended service life, and enhanced operational efficiency. With their superior hardness, wear resistance, reduced friction, and heat generation, ceramic balls enable bearings to operate at higher speeds while maintaining optimal performance. The corrosion resistance and electrical insulation properties of ceramic balls further enhance their suitability for various demanding applications. It is important to consider the specific operating conditions, load requirements, and speed limitations when selecting ceramic balls, as different ceramic materials offer varying benefits. By leveraging the unique properties of ceramic balls, industries can achieve higher reliability, longer maintenance intervals, and increased productivity in their angular contact ball bearing applications.

Send a message directly to us. We will contact you at once.