The manufacturing process of angular contact ball bearings

Abstract:

The manufacturing process of angular contact ball bearings involves a series of precise and quality-controlled steps, from material selection to assembly and packaging. By adhering to strict standards and utilizing advanced manufacturing techniques, manufacturers can produce high-quality bearings that meet the demanding requirements of various industrial applications.

Key words: Bearings, ball bearing, angular contact ball bearing, bearing manufacturing process

The manufacturing process of angular contact ball bearings involves several intricate steps to ensure precision, quality, and reliability in the final product. Here is an overview of the typical manufacturing process for angular contact ball bearings:

1. Material Selection:

- The manufacturing process begins with the selection of high-quality materials, typically steel or ceramic, for the bearing components such as the inner and outer raceways, balls, and cages.

2. Forging and Forming:

- The raw material is forged and formed into the desired shapes for the various bearing components. This process helps in aligning the grain structure of the material for improved strength and durability.

3. Turning and Grinding:

- The raceways, balls, and other components are machined to precise dimensions and a smooth surface finish through turning and grinding processes. This ensures proper fit and reduces friction during operation.

4. Heat Treatment:

- Heat treatment processes such as hardening and tempering are applied to the bearing components to enhance their hardness, toughness, and wear resistance.

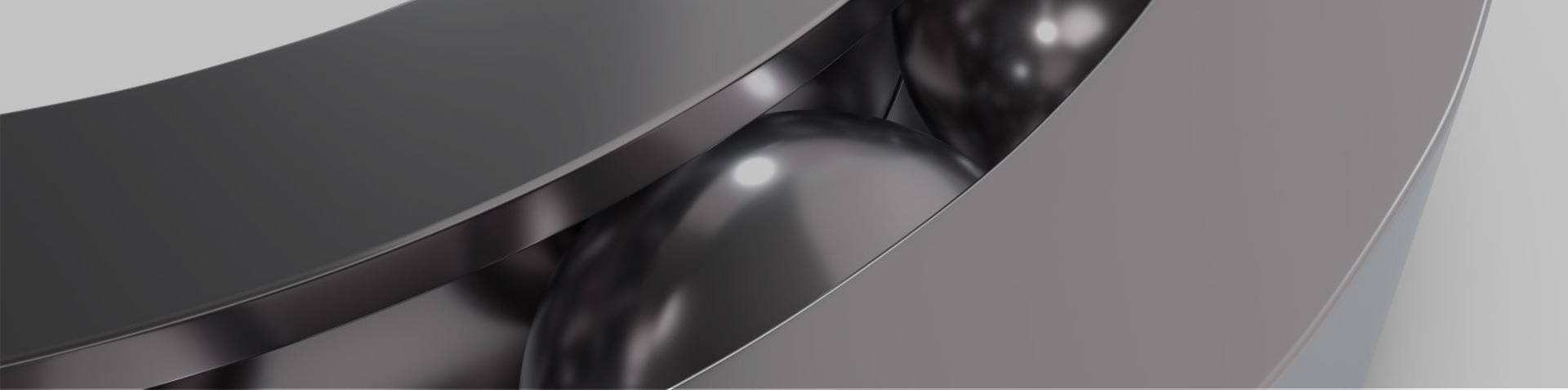

5. Ball Production:

- Balls used in angular contact ball bearings are manufactured with high precision. Processes such as cold heading, flashing, grinding, and lapping are employed to achieve the required dimensional accuracy and surface finish.

6. Assembly:

- The individual components, including the inner and outer raceways, balls, and cages, are assembled together with precision to form the complete angular contact ball bearing. Careful attention is paid to ensure proper alignment and clearance between components.

7. Lubrication:

- Lubrication is essential for reducing friction and wear in the bearing. During the manufacturing process, the bearings are lubricated with grease or oil to ensure smooth operation.

8. Quality Control:

- Quality control measures are implemented throughout the manufacturing process to check for dimensional accuracy, surface finish, hardness, and other critical parameters. Dimensional inspection, hardness testing, noise testing, and other quality checks are performed to ensure the bearings meet required specifications.

9. Packaging:

- Once the bearings pass quality control checks, they are packaged securely to protect them from damage during transportation and storage.

Conclusion:

The manufacturing process of angular contact ball bearings involves a series of precise and quality-controlled steps, from material selection to assembly and packaging. By adhering to strict standards and utilizing advanced manufacturing techniques, manufacturers can produce high-quality bearings that meet the demanding requirements of various industrial applications.