Home > News and Media > News and Events > Understanding the Versatility of Four-Contact Ball Bearings

Home > News and Media > News and Events > Understanding the Versatility of Four-Contact Ball Bearings

Abstract:

At its core, a four-contact ball bearing is a specialized type of bearing designed to endure both radial and axial loads in multiple directions. What sets it apart from conventional ball bearings is the presence of four points of contact between the balls and the inner and outer raceways. This unique configuration grants the bearing the ability to withstand not only radial and axial loads but also moment loads, making it adept at handling complex load scenarios.

Key words: Bearings, ball bearing, four point contact ball bearing

In the realm of mechanical engineering and industrial applications, the efficiency and reliability of machinery heavily rely on the performance of various components, with bearings playing a crucial role in ensuring smooth operation. Among the diverse types of bearings available, the four-contact ball bearing stands out as a versatile and robust solution for handling complex loads and dynamic forces.

Exploring the Basics

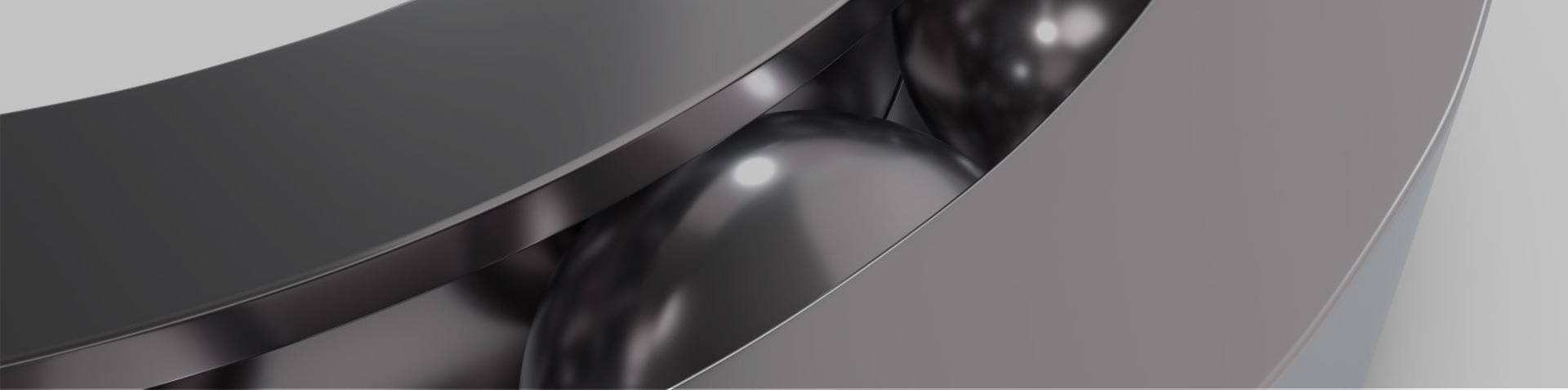

At its core, a four-contact ball bearing is a specialized type of bearing designed to endure both radial and axial loads in multiple directions. What sets it apart from conventional ball bearings is the presence of four points of contact between the balls and the inner and outer raceways. This unique configuration grants the bearing the ability to withstand not only radial and axial loads but also moment loads, making it adept at handling complex load scenarios.

Mechanism and Functionality

The design of a four-contact ball bearing allows it to distribute loads more evenly across the bearing elements, thereby reducing stress concentrations and enhancing load-carrying capacity. By providing four points of contact, this bearing type can accommodate higher thrust loads, making it suitable for applications where there are combined loads or varying force directions.

The four-point contact design enables the bearing to adjust to misalignments in the shaft or housing, ensuring smoother operation and reducing wear and tear on the machinery. Moreover, this design minimizes the need for additional components in the system, simplifying the overall design and maintenance requirements.

Applications and Advantages

Four-contact ball bearings find extensive use in a wide range of applications that demand precision, durability, and high load-carrying capacity. Industries such as robotics, machine tool spindles, aerospace, and automotive engineering rely on these bearings for their ability to perform under challenging conditions.

One of the key advantages of four-contact ball bearings is their versatility in handling complex loads and dynamic forces. Whether it’s in scenarios involving heavy radial loads, axial thrust, or moment loads, these bearings excel in providing reliable support and smooth operation. Their ability to accommodate misalignment and reduce friction contributes to enhanced efficiency and longevity in machinery and equipment.

Conclusion

In conclusion, the four-contact ball bearing represents a sophisticated engineering solution that addresses the demands of modern industrial applications. By offering a unique design with four points of contact, this type of bearing enhances load-carrying capacity, accommodates various load scenarios, and ensures smooth operation under challenging conditions.

As industries continue to push the boundaries of performance and efficiency, the versatility and reliability of four-contact ball bearings make them indispensable components in a wide array of machinery and equipment. Their ability to withstand complex loads and dynamic forces positions them as a cornerstone of precision engineering and mechanical excellence.

Send a message directly to us. We will contact you at once.