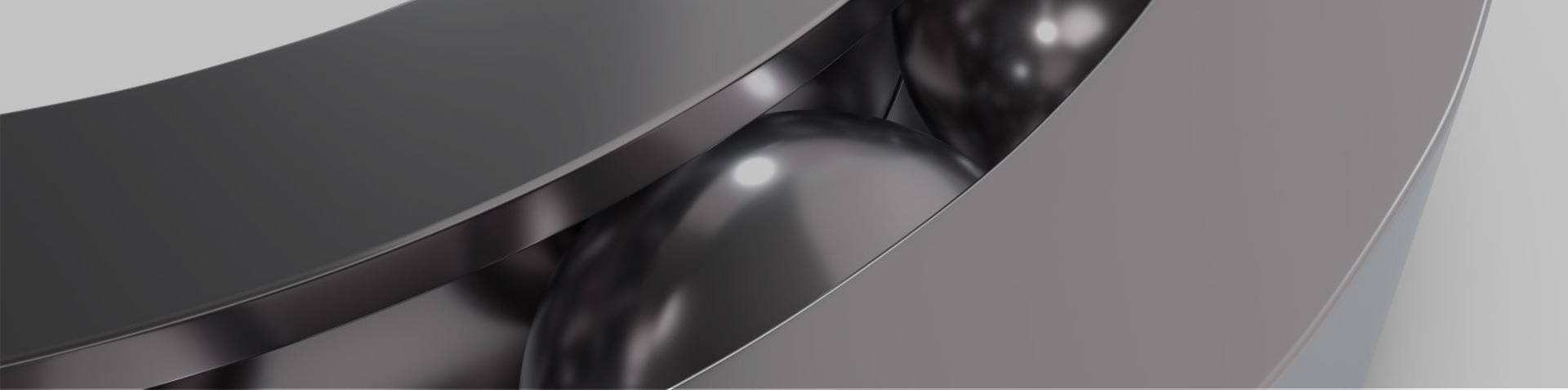

What factors affect the performance and lifespan of angular contact ball bearings?

Abstract:

By considering and addressing these factors, manufacturers and users of angular contact ball bearings can optimize performance, minimize the risk of premature failure, and extend the bearings’ operational lifespan in various industrial applications.

Key words: Bearings, angular contact ball bearing, design considerations, operating conditions, maintenance practices, environmental factors

The performance and lifespan of angular contact ball bearings are influenced by various factors, including design considerations, operating conditions, maintenance practices, and environmental factors. Here are some key factors that can affect the performance and lifespan of angular contact ball bearings:

1. Load and Speed:

- Excessive loads or speeds beyond the bearing’s design limits can lead to premature wear and failure. Properly matching the bearing to the application’s load and speed requirements is crucial for optimal performance and longevity.

2. Misalignment:

- Angular contact ball bearings are sensitive to misalignment. Excessive misalignment can cause uneven loading, increased friction, and premature wear. Proper alignment during installation is essential to ensure optimal performance and longevity.

3. Lubrication:

- Inadequate or improper lubrication can lead to increased friction, wear, and heat buildup, reducing the bearing’s lifespan. Regular lubrication with the correct type and amount of lubricant is essential for maintaining optimal performance and extending the bearing’s lifespan.

4. Contamination:

- Contaminants such as dust, dirt, moisture, and metal particles can adversely affect bearing performance and lifespan by causing abrasion, corrosion, and increased wear. Proper sealing and shielding, as well as maintaining clean operating environments, are essential to prevent contamination.

5. Temperature:

- High temperatures can degrade the lubricant and reduce the bearing’s effectiveness. Excessive heat can also lead to thermal expansion, which can affect the bearing’s internal clearances and performance. Monitoring and controlling operating temperatures are crucial for maximizing bearing lifespan.

6. Maintenance Practices:

- Regular inspection, monitoring, and maintenance practices, such as checking for signs of wear, lubrication levels, and alignment, can help identify potential issues early and prevent premature bearing failure. Proper handling and storage of bearings are also important for maintaining their performance and lifespan.

7. Installation:

- Proper installation techniques, including correct mounting, alignment, and preload settings, are essential for ensuring optimal bearing performance and longevity. Improper installation can lead to increased stress, misalignment, and premature failure.

8. Quality of Materials and Manufacturing:

- The quality of materials used in the bearing components and the precision of the manufacturing process can significantly impact the bearing’s performance and lifespan. High-quality materials and advanced manufacturing techniques can result in bearings with superior durability and reliability.

By considering and addressing these factors, manufacturers and users of angular contact ball bearings can optimize performance, minimize the risk of premature failure, and extend the bearings’ operational lifespan in various industrial applications.